Water Manifold 1.5″ x 3/4″SB (4PT)

£3.11 Inc VAT

80 in stock

Water Manifold 1.5″ x 3/4″ SB (4PT): The Heart of Your Hot Tub’s Water System

Introduction

As a hot tub enthusiast and spare parts supplier, I’m excited to introduce you to the Water Manifold 1.5″ x 3/4″ SB (4PT). This crucial component plays a vital role in your hot tub’s circulation system, ensuring a smooth and efficient flow of water to your jets. Let me walk you through the features and benefits of this high-quality part.

Product Overview

The Water Manifold 1.5″ x 3/4″ SB (4PT) is a precision-engineered component manufactured by Las Water60, a trusted name in the hot tub industry. This manifold is designed to distribute water effectively from your pump to multiple jets, enhancing your hot tub experience.

Key Features:

- Durable construction for long-lasting performance

- Precision-engineered for optimal water flow

- Compatible with standard 1.5-inch piping systems

- Four 3/4-inch smooth barb outlets for versatile jet connections

Technical Specifications

To help you understand the product better, I’ve compiled a detailed specifications table:

| Specification | Details |

|---|---|

| Type | Water Manifold |

| Manufacturer | Las Water60 |

| Main Body Size | 1.5″ S x 1.5″ Spg |

| Outlet Size | 3/4″ (4) smooth barb |

| Internal Diameter (male end) | 48 mm |

| Internal Diameter (female end) | 57 mm |

| Outer Length | 132 mm |

| Depth | 95 mm |

| Material | High-grade, chemical-resistant PVC |

Installation and Compatibility

This water manifold is designed for easy integration into your hot tub’s plumbing system. It’s compatible with both 1.5-inch rigid pipe and 1.5-inch flexible pipe, offering versatility in your setup.

Installation Tips:

- Clean all surfaces with a quality plumbing cleaner before assembly.

- Use appropriate pipe cement for a secure, watertight seal.

- For the female end, insert the pipe work inside the manifold.

- For the male end, insert it into a female socket of your plumbing system.

Purpose and Function

The primary function of this water manifold is to efficiently distribute water from your hot tub’s pump to multiple jets. It acts as a central hub in your plumbing system, ensuring that each jet receives the right amount of water pressure for optimal performance.

Benefits of Upgrading

By installing or upgrading to this Water Manifold 1.5″ x 3/4″ SB (4PT), you can expect:

- Improved water circulation in your hot tub

- Enhanced jet performance for a more satisfying massage experience

- Better overall efficiency of your hot tub’s plumbing system

- Potential energy savings due to optimized water flow

Maintenance and Care

To ensure the longevity and performance of your water manifold:

- Regularly inspect for any signs of wear or damage

- Keep the manifold clean and free from debris

- Check connections periodically to ensure they remain tight and leak-free

Conclusion

The Water Manifold 1.5″ x 3/4″ SB (4PT) is more than just a plumbing component – it’s an essential part of your hot tub’s circulatory system. By choosing this high-quality manifold, you’re investing in the performance and longevity of your hot tub. Whether you’re replacing an old part or upgrading your system, this water manifold is an excellent choice for any hot tub owner looking to optimize their spa experience.

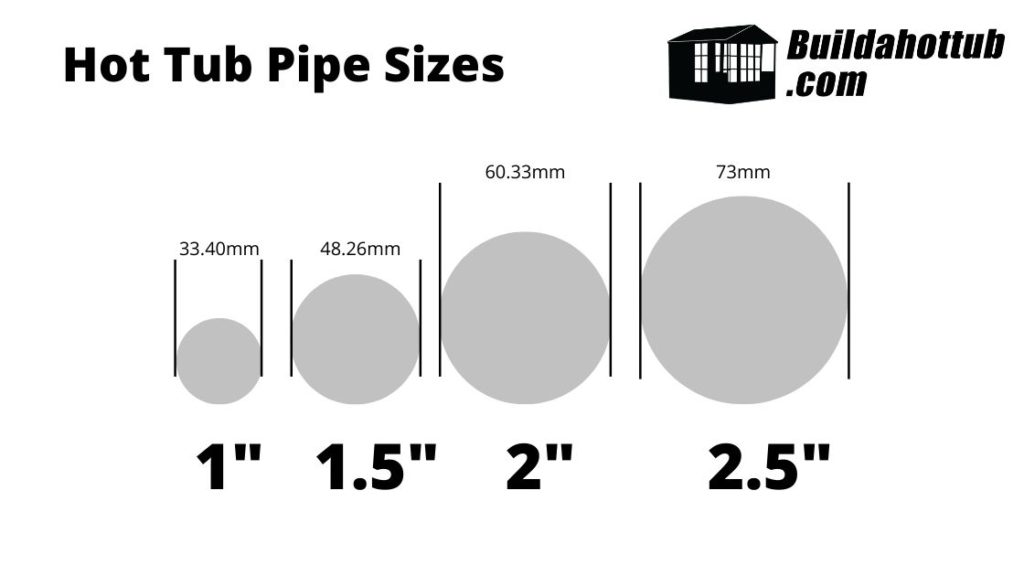

USA Imperial is the Standard

All hot tubs and their fittings are designed for USA standard of Imperial pipe. Would you believe that for example, a European 2.5″ pipe is different from a USA 2.5″ pipe – well it is and there is just over 2mm difference and it makes a huge difference as it doesn’t fit!

You must make sure that you are using American standard sized pipe – always worth checking with your supplier before you purchase.

Can I convert Metric pipe to Imperial?

Yes, you can convert metric pipe to imperial, usually there is a socket connection that will do that. However, what I would preface that with is really, the only reason you would want to do that is say if you have a long run of pipe between your control room and your hot tub. You cant easily get imperial pipe supply but you have found say 75mm pipe that would do the job.

In this instance, it would work to convert it down at each end.

However, what you cannot do (technically you can but it is a real mess to do so) is convert all of the pipework to metric using adaptors. Generally, this just doesn’t work, costs loads in just adaptors alone and the amount of joints means you are going to have some leaks!

What rating of pipe do I need?

Pipe is rated to different pressures. You must use pressure rated pipe on your hot tub build as it is a pressurised system. In general, any pipe that is rated to 130 PSI or 9 BAR can be used on a hot tub build. This is often referred to as Class C. Likewise, Class E which is rated to 15 BAR or 218 PSI is also commonly found on hot tub builds.

Anything less than 130 PSI or 9 BAR should not be used – the pipes are not waste water pipes that are commonly found in hardware stores. They must be pressure rated and you will see this printed on the side of all the pipe so there will be no confusion.

What about Schedule 40 Pipe?

The schedule number on pipe correlates to the thickness of the wall on the pipe: as the number increases, the thicker the wall thickness is. Also, what is interesting is that while the schedule number can be the same on different sized pipes, the actual wall thickness will be different.

However, for our DIY Hot Tubs, we would only opt for schedule 40 – schedule 80 would be an overkill.

We also only use schedule 40 pipe if it is being buried and there is considerable weight on it. What I mean by this is that you need the physical strength of the pipe to stop it being crushed and cracked. In most cases, regular pressure rated pipe is just fine.

Should I use Rigid or Semi-Flexible Pipe?

When I built my own hot tub, I opted for semi-flexible as I though that it would be a little more forgiving. It is, however it is now my experience that the fact it is forgiving, and I use that in a loosest of terms as it is still pretty rigid pipe, it is more likely to leak.

The reason that it is more likely to leak is that you can “force” the joint when there is a little bit of give in the pipe. If you force the joint as I have said many times on this blog and on my YouTube Channel, you are going to have leaks – and it did!

For that reason, wherever possible today I recommend that you use rigid pipe. You have to make a good joint and it has to be accurate. It is forcing your workmanship which you will benefit from in the long run. Rigid pipe is the way forward for your DIY Hot Tub build.

Support your Pipework

If you pick up a length of pipe, 2m/6ft, there is not a lot of weight in it at all. However, if you fill that same pipe with water, cap it off each end and try to lift it, you will notice there is a huge weight increase. Water is heavy. If you have long runs of pipe, you must support them. Whether this is in ground and they should be laid correctly with a gravel base or if it is on your hot tub, they should be tied and pinned to the block work.

If you dont support your pipes and they fill with water, you can put strain on the joints that over time, will work their way loose and leak. It only takes a couple of minutes to tie your pipes and support them and it will save a whole bunch of time and money on repairs in the future by getting this right from the start.

Making the perfect joint with PVC pipe cement.

On this blog and on my YouTube Channel I talk a lot about making the correct joints and that a well made joint doesn’t leak. So, how do you make a well made joint?

- Make sure when you cut the pipes you are cutting them at 90 degrees so they fit into the fittings correctly.

- Make sure you remove any rough edges from your cuts

- Ensure you are roughing up 3″ of the pipe with sand paper before you make the connection

- Apply PVC Pipe Cement to the pipe and the connection

- Twist the pipe or fitting as you are inserting it to prevent “channeling” which leads to leaks

- Make sure the pipe goes all the way into the fitting (always a good idea to mark the ideal depth you want to get to)

- Wipe off any excess pipe cement.

- Allow to cure for 4 hours for full strength

| Part# | 672-4150 |

|---|

You may also like…

Plumbing and Other

Plumbing and Other

Plumbing and Other

Plumbing and Other

Plumbing and Other

3 quarter inch vinyl water pipe (per metre) (PLEASE SEE ADDITIONAL NOTES)

Plumbing and Other

Related products

Chemicals & Accessories

Chemicals & Accessories

Plumbing and Other

3/8 inch vinyl air pipe (per metre) (PLEASE SEE ADDITIONAL NOTES)

Plumbing and Other