2 inch Flapper Check Valve 1.25-2lbs. Spring

£12.66 Inc VAT

52 in stock

2-inch Flapper Check Valve: The Heart of Your Hot Tub’s Circulation

As a dedicated hot tub enthusiast and spare parts supplier, I’m excited to introduce you to a crucial component that keeps your spa running smoothly: the 2-inch Flapper Check Valve with a 1.25-2lbs Spring. This small but mighty piece of equipment plays a vital role in maintaining proper water flow and ensuring the longevity of your hot tub system.

What Is a Flapper Check Valve?

A flapper check valve is a type of one-way valve that allows water to flow in one direction while preventing backflow. It’s an essential part of your hot tub’s plumbing system, helping to maintain optimal water circulation and pressure.

Why Choose This Particular Valve?

This 2-inch Flapper Check Valve, manufactured by Las Water72, is designed to meet the needs of various hot tub models, including Spaform Spas and many others. Its versatility and reliability make it a popular choice among hot tub owners and maintenance professionals alike.

Key Features:

- Robust Construction: Built to withstand the demands of hot tub environments

- Precise Flow Control: 1.25-2lbs spring ensures consistent performance

- Universal Compatibility: Fits most 2-inch pipe systems, both rigid and flexible

Technical Specifications

To help you make an informed decision, here’s a detailed breakdown of the valve’s specifications:

| Specification | Detail |

|---|---|

| Type | One-way flapper valve |

| Manufacturer | Las Water72 |

| Size | 2″ S x 2″ S |

| Spring Strength | 1.25-2lbs |

| Outer Length | 105mm |

| Outer Height | 69mm |

| Outer Depth | 69mm |

| Internal Diameter | 61mm |

Applications and Benefits

This versatile valve serves multiple purposes in your hot tub system:

- Backflow Prevention: It stops water from flowing in the wrong direction, protecting your pump and other components.

- Flow Restriction: By controlling water flow, it helps balance your spa’s circulation system.

- Enhanced Circulation: It can be used to direct water more effectively through your hot tub’s various features.

Installation and Compatibility

The 2-inch Flapper Check Valve is designed for easy integration into your existing system. It’s compatible with:

- 2-inch rigid pipes

- 2-inch flexible rigid pipes

- Various spa models, including Spaform Spas and many others

Its standard size and configuration make it a great replacement part for many hot tub systems.

Maintaining Your Hot Tub’s Performance

By incorporating this high-quality flapper check valve into your hot tub’s plumbing, you’re taking a significant step towards ensuring optimal performance and longevity. It’s a small investment that can make a big difference in your spa experience.

Remember, regular maintenance and using the right parts are key to keeping your hot tub in top condition. This 2-inch Flapper Check Valve is just one of the many quality components I offer to help you maintain your spa and enjoy worry-free relaxation.

Feel free to reach out if you have any questions about this valve or need advice on other hot tub components. I’m here to help you make the most of your spa experience!

What is a check valve on a hot tub?

A check valve, also known as a one-way or non-return valve, is a mechanical device used in hot tub plumbing systems (and other hydraulic systems) to control the flow of water or other fluids in one direction only. It allows water to flow in one direction while preventing backflow or reverse flow.

In a hot tub, check valves are typically installed in the plumbing lines to serve several important functions:

-

Preventing Backflow: One of the primary functions of a check valve in a hot tub is to prevent water from flowing backward through the plumbing system. This is especially crucial in situations where there are multiple components, such as pumps and heaters, that can have water flow in and out. Backflow prevention ensures that water flows in the desired direction and does not damage or interfere with other components.

-

Protecting Equipment: Check valves help protect hot tub equipment from potential damage caused by water backflow. For example, a check valve can prevent water from flowing back into a pump, which could cause damage to the impeller or motor.

-

Maintaining Water Level: In some hot tubs, check valves are used in the water supply line to help maintain a consistent water level. These valves allow water to flow into the tub but prevent it from flowing back out when the tub's pumps are turned off.

-

Air Injection Systems: In hot tubs equipped with air injection systems, check valves are often used to control the flow of air into the water. They ensure that air is drawn into the system when needed but does not escape or backflow into the air lines.

-

Waterfall or Fountain Features: Hot tubs with waterfall or fountain features may use check valves to control the direction of water flow, ensuring that water flows down the waterfall or into the fountain but does not backflow into the plumbing.

Check valves come in various designs, including swing-check valves, ball check valves, and diaphragm check valves. The specific type of check valve used in a hot tub depends on the application and the manufacturer's design.

Overall, check valves are essential components in hot tub plumbing systems, helping to maintain proper water circulation, protect equipment, and ensure the efficient operation of the hot tub.

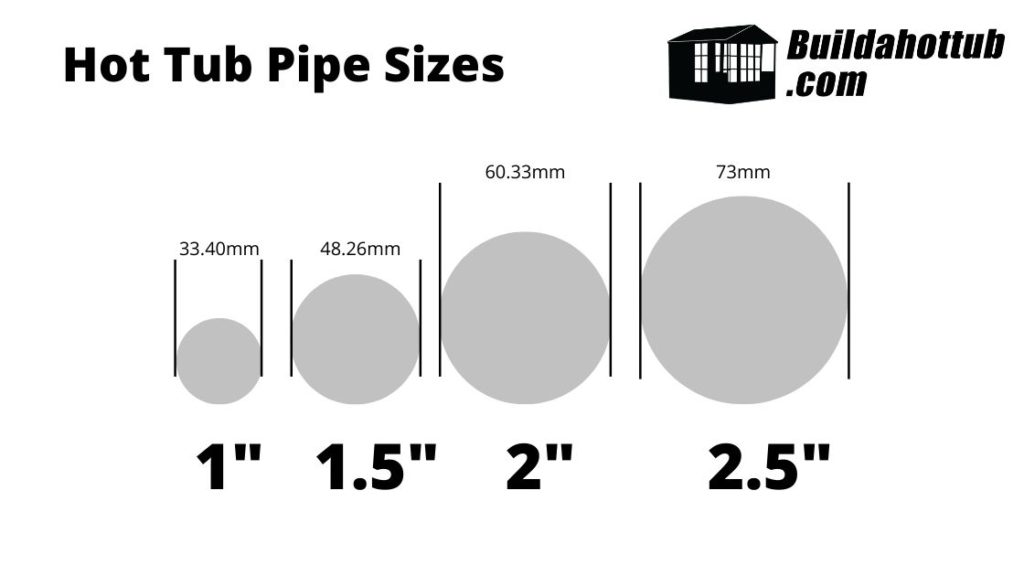

USA Imperial is the Standard

All hot tubs and their fittings are designed for USA standard of Imperial pipe. Would you believe that for example, a European 2.5″ pipe is different from a USA 2.5″ pipe – well it is and there is just over 2mm difference and it makes a huge difference as it doesn’t fit!

You must make sure that you are using American standard sized pipe – always worth checking with your supplier before you purchase.

Can I convert Metric pipe to Imperial?

Yes, you can convert metric pipe to imperial, usually there is a socket connection that will do that. However, what I would preface that with is really, the only reason you would want to do that is say if you have a long run of pipe between your control room and your hot tub. You cant easily get imperial pipe supply but you have found say 75mm pipe that would do the job.

In this instance, it would work to convert it down at each end.

However, what you cannot do (technically you can but it is a real mess to do so) is convert all of the pipework to metric using adaptors. Generally, this just doesn’t work, costs loads in just adaptors alone and the amount of joints means you are going to have some leaks!

What rating of pipe do I need?

Pipe is rated to different pressures. You must use pressure rated pipe on your hot tub build as it is a pressurised system. In general, any pipe that is rated to 130 PSI or 9 BAR can be used on a hot tub build. This is often referred to as Class C. Likewise, Class E which is rated to 15 BAR or 218 PSI is also commonly found on hot tub builds.

Anything less than 130 PSI or 9 BAR should not be used – the pipes are not waste water pipes that are commonly found in hardware stores. They must be pressure rated and you will see this printed on the side of all the pipe so there will be no confusion.

What about Schedule 40 Pipe?

The schedule number on pipe correlates to the thickness of the wall on the pipe: as the number increases, the thicker the wall thickness is. Also, what is interesting is that while the schedule number can be the same on different sized pipes, the actual wall thickness will be different.

However, for our DIY Hot Tubs, we would only opt for schedule 40 – schedule 80 would be an overkill.

We also only use schedule 40 pipe if it is being buried and there is considerable weight on it. What I mean by this is that you need the physical strength of the pipe to stop it being crushed and cracked. In most cases, regular pressure rated pipe is just fine.

Should I use Rigid or Semi-Flexible Pipe?

When I built my own hot tub, I opted for semi-flexible as I though that it would be a little more forgiving. It is, however it is now my experience that the fact it is forgiving, and I use that in a loosest of terms as it is still pretty rigid pipe, it is more likely to leak.

The reason that it is more likely to leak is that you can “force” the joint when there is a little bit of give in the pipe. If you force the joint as I have said many times on this blog and on my YouTube Channel, you are going to have leaks – and it did!

For that reason, wherever possible today I recommend that you use rigid pipe. You have to make a good joint and it has to be accurate. It is forcing your workmanship which you will benefit from in the long run. Rigid pipe is the way forward for your DIY Hot Tub build.

Support your Pipework

If you pick up a length of pipe, 2m/6ft, there is not a lot of weight in it at all. However, if you fill that same pipe with water, cap it off each end and try to lift it, you will notice there is a huge weight increase. Water is heavy. If you have long runs of pipe, you must support them. Whether this is in ground and they should be laid correctly with a gravel base or if it is on your hot tub, they should be tied and pinned to the block work.

If you dont support your pipes and they fill with water, you can put strain on the joints that over time, will work their way loose and leak. It only takes a couple of minutes to tie your pipes and support them and it will save a whole bunch of time and money on repairs in the future by getting this right from the start.

Making the perfect joint with PVC pipe cement.

On this blog and on my YouTube Channel I talk a lot about making the correct joints and that a well made joint doesn’t leak. So, how do you make a well made joint?

- Make sure when you cut the pipes you are cutting them at 90 degrees so they fit into the fittings correctly.

- Make sure you remove any rough edges from your cuts

- Ensure you are roughing up 3″ of the pipe with sand paper before you make the connection

- Apply PVC Pipe Cement to the pipe and the connection

- Twist the pipe or fitting as you are inserting it to prevent “channeling” which leads to leaks

- Make sure the pipe goes all the way into the fitting (always a good idea to mark the ideal depth you want to get to)

- Wipe off any excess pipe cement.

- Allow to cure for 4 hours for full strength

| Part# | 550-6810 |

|---|

You may also like…

Plumbing and Other

Plumbing and Other

Plumbing and Other

Plumbing and Other

Related products

Plumbing and Other

Plumbing and Other

Plumbing and Other

Air Jets and Jet Parts

Plumbing and Other

Plumbing and Other

3 quarter inch vinyl water pipe (per metre) (PLEASE SEE ADDITIONAL NOTES)