1 Inch Threaded Nipple for 5KW Vian Heat Pumps

£5.03 Inc VAT

47 in stock

1 Inch Threaded Nipple – Vian 5KW Heat Pump Component

Product Overview

As a retailer of hot tub parts, I’m featuring this essential 1 inch threaded nipple specifically designed for Vian 5KW heat pump installations. This component ensures proper plumbing connections for optimal heat pump performance.

Features and Benefits

The threaded nipple provides secure, watertight connections for Vian heat pump plumbing systems. Manufactured to precise specifications, this component ensures reliable operation and easy installation or replacement when servicing Vian 5KW heat pump units.

Applications

This threaded nipple is specifically designed for use with Vian HP-V500 and HP-V501 5KW heat pump models. It’s an essential component for both new installations and maintenance repairs.

Technical Specifications

| Specification | Detail |

|---|---|

| Type | Threaded Nipple |

| Size | 1 inch |

| Manufacturer | Vian |

| Compatible Models | HP-V500, HP-V501 |

| Material | High-grade plumbing plastic |

| Application | Heat Pump Connection |

Design Features

The 1-inch size ensures proper flow rates for optimal heat pump performance. The threading is precisely engineered to provide secure, leak-free connections in heat pump applications.

Compatibility

Specifically designed for use with Vian 5KW heat pump models HP-V500 and HP-V501. Essential for maintaining proper plumbing connections in these systems.

Heat Pumps: The Smart Way to Warm Your Pool and Hot Tub

What Are Heat Pumps?

Looking for an energy-efficient way to keep your pool or hot tub at the perfect temperature? Heat pumps work like your refrigerator in reverse – they capture heat from the surrounding air and transfer it to your water, rather than generating heat directly like traditional gas or electric heaters.

The Efficiency Advantage

The magic lies in their efficiency. While traditional heaters might convert 80-90% of their energy into heat, heat pumps can deliver up to 600% efficiency. This means for every unit of electricity used, they can generate up to 6 units of heat energy. Over time, this translates into significant savings on your energy bills, despite a higher upfront cost.

Understanding the Limitations

Heat pumps work best when ambient temperatures are above 50°F (10°C). In colder climates, their efficiency drops, though newer models are pushing these boundaries with improved cold-weather performance. They also heat water more slowly than gas heaters, requiring more planning for temperature management.

Hot Tub Applications

For hot tub owners, heat pumps present a particularly attractive option. Since hot tubs maintain a constant temperature, the steady, efficient heating of a heat pump can substantially reduce operating costs. Many users report cutting their heating expenses by 50-75% after switching from electric resistance heaters.

Making the Right Choice

When considering a heat pump, factor in:

- Your local climate and typical ambient temperatures throughout the swimming season

- Your usage patterns and how quickly you need to heat the water

- The desired temperature range for your pool or hot tub

- Initial investment versus long-term energy savings

- Environmental impact and carbon footprint considerations

Sizing Your Heat Pump

The key to maximizing efficiency is proper sizing. An undersized unit will struggle to maintain temperature, while an oversized one wastes money. Work with a qualified pool professional to calculate your specific needs based on:

- Water volume

- Desired temperature rise

- Local climate conditions

- Pool or hot tub surface area

- Typical wind exposure

- Whether you use a pool cover

Conclusion

While heat pumps require a higher initial investment, their superior efficiency and lower operating costs make them an attractive option for pool and hot tub owners. With proper sizing and installation, they can provide reliable, cost-effective heating while reducing your environmental impact

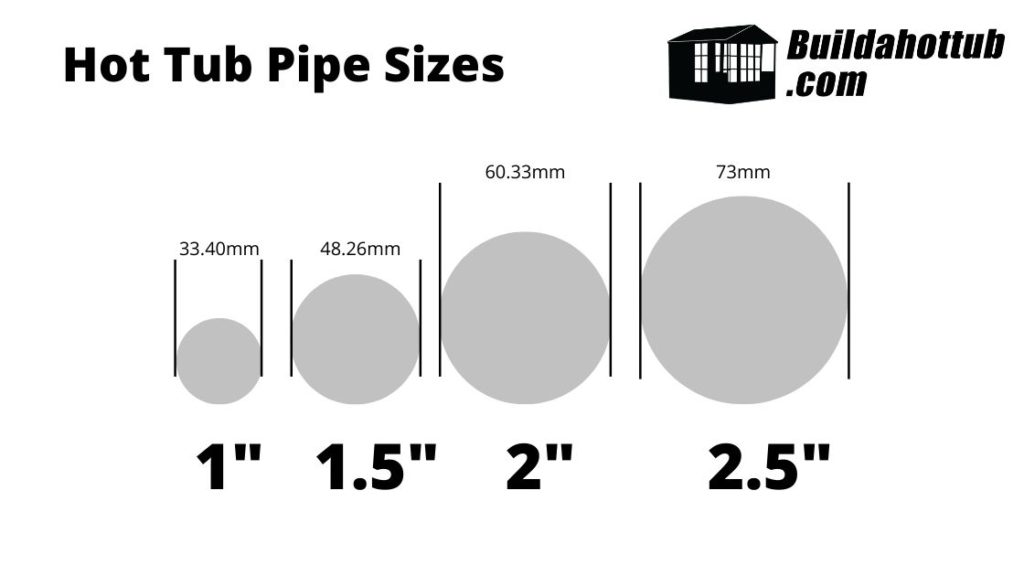

USA Imperial is the Standard

All hot tubs and their fittings are designed for USA standard of Imperial pipe. Would you believe that for example, a European 2.5″ pipe is different from a USA 2.5″ pipe – well it is and there is just over 2mm difference and it makes a huge difference as it doesn’t fit!

You must make sure that you are using American standard sized pipe – always worth checking with your supplier before you purchase.

Can I convert Metric pipe to Imperial?

Yes, you can convert metric pipe to imperial, usually there is a socket connection that will do that. However, what I would preface that with is really, the only reason you would want to do that is say if you have a long run of pipe between your control room and your hot tub. You cant easily get imperial pipe supply but you have found say 75mm pipe that would do the job.

In this instance, it would work to convert it down at each end.

However, what you cannot do (technically you can but it is a real mess to do so) is convert all of the pipework to metric using adaptors. Generally, this just doesn’t work, costs loads in just adaptors alone and the amount of joints means you are going to have some leaks!

What rating of pipe do I need?

Pipe is rated to different pressures. You must use pressure rated pipe on your hot tub build as it is a pressurised system. In general, any pipe that is rated to 130 PSI or 9 BAR can be used on a hot tub build. This is often referred to as Class C. Likewise, Class E which is rated to 15 BAR or 218 PSI is also commonly found on hot tub builds.

Anything less than 130 PSI or 9 BAR should not be used – the pipes are not waste water pipes that are commonly found in hardware stores. They must be pressure rated and you will see this printed on the side of all the pipe so there will be no confusion.

What about Schedule 40 Pipe?

The schedule number on pipe correlates to the thickness of the wall on the pipe: as the number increases, the thicker the wall thickness is. Also, what is interesting is that while the schedule number can be the same on different sized pipes, the actual wall thickness will be different.

However, for our DIY Hot Tubs, we would only opt for schedule 40 – schedule 80 would be an overkill.

We also only use schedule 40 pipe if it is being buried and there is considerable weight on it. What I mean by this is that you need the physical strength of the pipe to stop it being crushed and cracked. In most cases, regular pressure rated pipe is just fine.

Should I use Rigid or Semi-Flexible Pipe?

When I built my own hot tub, I opted for semi-flexible as I though that it would be a little more forgiving. It is, however it is now my experience that the fact it is forgiving, and I use that in a loosest of terms as it is still pretty rigid pipe, it is more likely to leak.

The reason that it is more likely to leak is that you can “force” the joint when there is a little bit of give in the pipe. If you force the joint as I have said many times on this blog and on my YouTube Channel, you are going to have leaks – and it did!

For that reason, wherever possible today I recommend that you use rigid pipe. You have to make a good joint and it has to be accurate. It is forcing your workmanship which you will benefit from in the long run. Rigid pipe is the way forward for your DIY Hot Tub build.

Support your Pipework

If you pick up a length of pipe, 2m/6ft, there is not a lot of weight in it at all. However, if you fill that same pipe with water, cap it off each end and try to lift it, you will notice there is a huge weight increase. Water is heavy. If you have long runs of pipe, you must support them. Whether this is in ground and they should be laid correctly with a gravel base or if it is on your hot tub, they should be tied and pinned to the block work.

If you dont support your pipes and they fill with water, you can put strain on the joints that over time, will work their way loose and leak. It only takes a couple of minutes to tie your pipes and support them and it will save a whole bunch of time and money on repairs in the future by getting this right from the start.

Making the perfect joint with PVC pipe cement.

On this blog and on my YouTube Channel I talk a lot about making the correct joints and that a well made joint doesn’t leak. So, how do you make a well made joint?

- Make sure when you cut the pipes you are cutting them at 90 degrees so they fit into the fittings correctly.

- Make sure you remove any rough edges from your cuts

- Ensure you are roughing up 3″ of the pipe with sand paper before you make the connection

- Apply PVC Pipe Cement to the pipe and the connection

- Twist the pipe or fitting as you are inserting it to prevent “channeling” which leads to leaks

- Make sure the pipe goes all the way into the fitting (always a good idea to mark the ideal depth you want to get to)

- Wipe off any excess pipe cement.

- Allow to cure for 4 hours for full strength

You may also like…

Plumbing and Other

Plumbing and Other

Plumbing and Other

Plumbing and Other

Related products

Chemicals & Accessories

Plumbing and Other

Plumbing and Other

3/8 inch vinyl air pipe (per metre) (PLEASE SEE ADDITIONAL NOTES)

Plumbing and Other

Plumbing and Other

Plumbing and Other

Plumbing and Other