4 Jet, Gunite Body Pack

£349.00 Inc VAT

This pack contains 4 x Jets, 4 x Gunite Bodies, 1m of 1″ Pipe and 1m of 2.5″ Gunite Pipe. These are suitable for block built and concrete poured hot tubs.

What are Gunite Jet Bodies?

If you have seen the awesome YouTube videos that show shotcrete or Gunite concrete being sprayed into a wireframe to create a pool, then you will have seen these parts before. It takes some highly skilled labourers then skim it flat to form the surface of the pool. This is not the style of Hot Tub we can build in our own back yards. However, If you are thinking about building a concrete hot tub or cinder block hot hot, even a brick hot tub, you are going to need some jets.

The jets are going to need to get through the walls and the Gunite bodies are exactly how this happens.

Above is my Hot Tub build. There are two sets of pipe that are connecting to what are known as Gunite Jet Bodies. You can also see that it is the Gunite Jet Bodies that then allow the pipes to get through the wall and into the Hot Tub through holes in the brickwork.

How Do Gunite Jet Bodies Work?

The two sets of pipework that you can see carry water (in the larger 2″ pipe at the bottom” and air (in the smaller 1.5″ pipe on the top) into the Gunite Bodies. This water and air then mixes in the Gunite get body and in the process forms a much stronger powered jet that then flows back into the Hot Tub. You can really feel the difference if you turn your pump onto full power without the air blower running. Switch on the air blower, and the power of the jet dramatically increases.

The water and the air lines are separate but as you might expect, it is possible when the blower is not running for water to get into the air pipework. This is not a problem as long as you have a non-return valve fitted to your blower. The last thing you want is a blower (which is really like a hair dryer on steroids) full of water. Why? As you might expect your electricity will be tripping for sure! Water and electricity do not mix.

What do Gunite Jet Bodies Consist of?

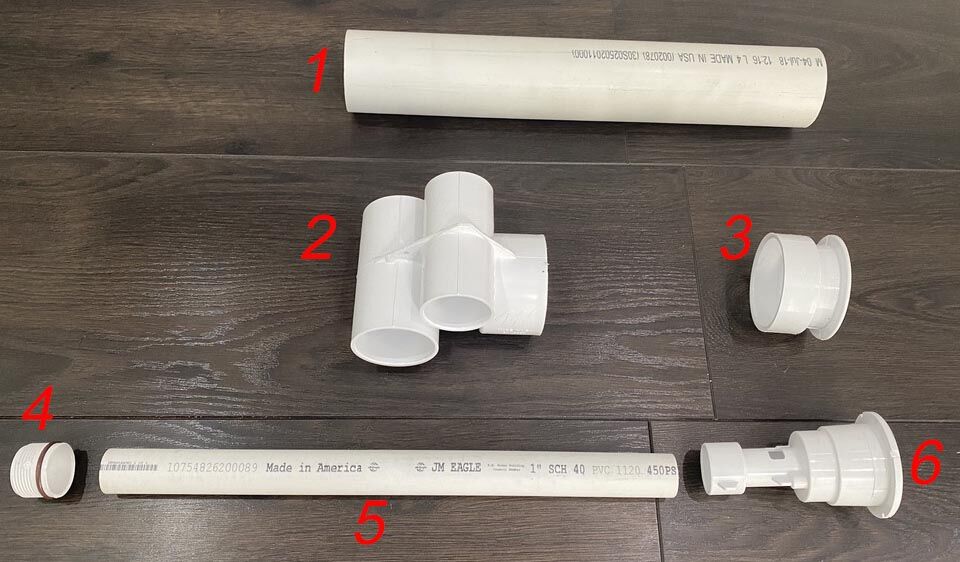

There are 6 parts to a Gunite Jet body

- 2.5″ Rigid Water Pipe

- Gunite Jet Body

- End Cap

- 1″ thread

- 1″ Rigid Water Pipe

- Jet Nozzle Holder

Decision Time.

Before you assemble the jet body, you need to decide if you are going to connect the external air and water pipes first. Or, are you going to assemble the jet bodies but not fix them in place until the air and water pipes have been connected. This is really a decision you will have to make on site and depends on how close the jets are to each other. The closer they are, the harder it is to get even the “flexible” pipe into the holes on either side of the jet bodies; they can be very tight. It can be easier to assemble the exterior pipework first with the jet bodies then push them through the holes. This was how I did it. The decision is up to you.

How do you assemble a Gunite Jet Body?

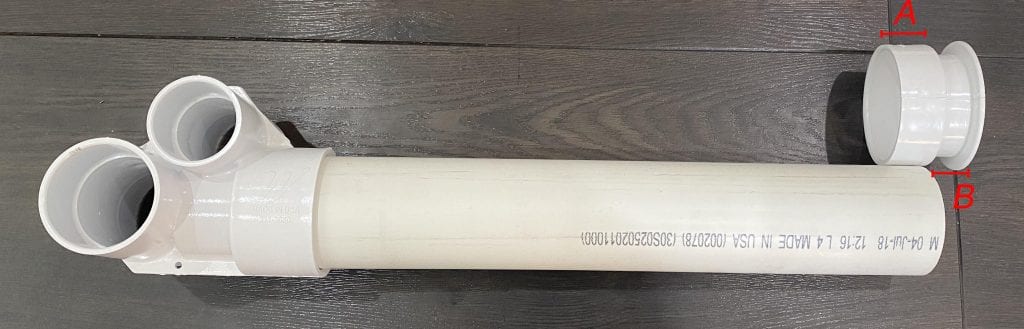

Assembling the Gunite Jet Body is not too difficult. (part 1), the Rigid Water Pipe slots into part 2 and is cemented into place with Pipe cement. The pipe cement is applied onto the inner portion of the Jet Body (part 2) before the rigid pipe is inserted.

It is at this point that you are now going to insert the jet body through the 2.5″ holes that you have drilled in your block-work. As you can probably see on the pictures above, the end cap, (part 3) is slightly wider than the 2.5″ pipe. Therefore, you may need to chisel away a little at your holes to make them fit.

At this point, you are going to mark the length of pipe for cutting. There are a few things to note here.

If you look at the picture below, you will see that the end cap does not fit right to the end. Therefore, if you are measuring the length of the pipe you need, you need to allow for the fact that it is going to be longer.

The end cap (part 3) will sit approximately 30mm (1.18″) onto the end of the pipe as shown in the image above marked “A”. This means that 30mm (1.18″) of the hole in the brick need to be about 4mm wider to allow for the fitting to fit snugly into the hole.

It will also protrude 25mm (0.98″) (marked “B”) from the end of the pipe. The goal is to get (part 3) the end cap to sit flush with your finished surface. Therefore, if you are going to tile, you need to allow for this. If you look at my tub below, you will see that I allowed extra depth for the tiles so they are protruding about 10mm out from the brickwork. This was to allow a thin coat of render and an 8mm tile.

When you then add the tiles as you can see below, this fitting should be flush as we can move onto the next step.

Before you get to any form of tiling, you are going to want to seal around the jet body itself to make it water tight. You should do this front and back unless you are sinking them into concrete. You can either do this with an epoxy resin or as I did, use a waterproofed concrete mix to plug all the gaps. Afterwards as you can see in the pictures above, the gaps were then filled with the waterproof tile grout too.

Assembling the Air Pipe and Jet Holder

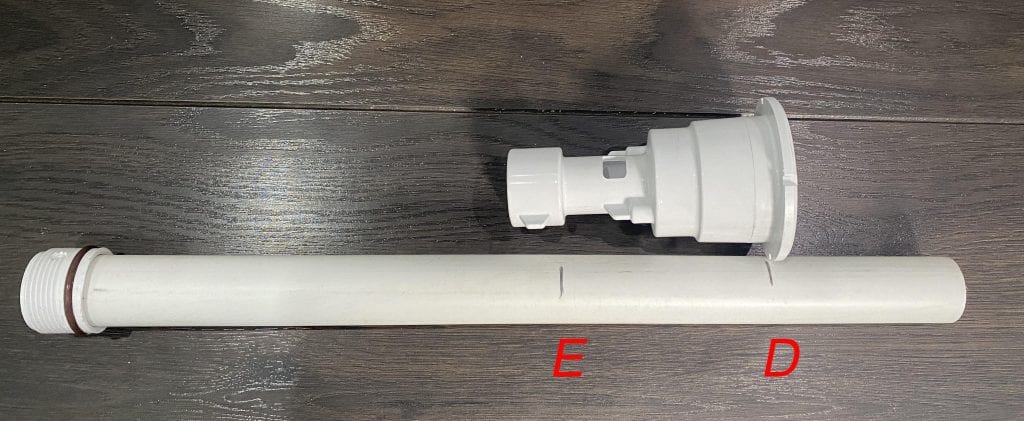

Firstly, you need to pipe cement part 4, the screw cap onto part 5 the rigid air pipe as shown below.

This allows for you to then screw in the pipe into the jet body. The picture below shows just how this works without the water pipe being attached. This is just for informational purposes. At this point, your jet bodies should be well and truly fixed into the walls!

With the jets in the wall, and the air pipes screwed in, you should now be looking at something like this.

What you now need to do is take a straight edge and mark the flush point on the air pipes. DO NOT CUT THIS YET!

You’ve marked how long the total length of the pipe should be to sit flush with your finished surface. (Marked “D” on the photo below) However, you need to allow for the jet nozzle holder (Part 6) which is longer than pipe.

What you actually have to do, is measure back from your marked pipe to find your actual cutting length which is marked “E” on the photo below. I would allow a few mm less (so cut pipe on the left hand side of this mark) This is because the fitting never go 100% into the housing.

You can now cut the water pipe, just to the left of your mark (“E” on the photo) You then will need to pipe cement part 6, the Jet Nozzle holder onto the end of the air pipe that you have just cut.

You can now screw the Air Pipe into the Jet Body and you will see that it will sit flush with your final surface.

All that is left is to either push in your jets if you have the push in type, or screw in your jets if you have the screw in type. You jets will now look something like my tub below.

And there we have it. Gunite Jet Body assembly and installation de-mystified. Hope you found this article useful.

Related products

Plumbing and Other

Plumbing and Other

Chemicals & Accessories

Plumbing and Other

Plumbing and Other

Plumbing and Other

3/8 inch vinyl air pipe (per metre) (PLEASE SEE ADDITIONAL NOTES)

Plumbing and Other